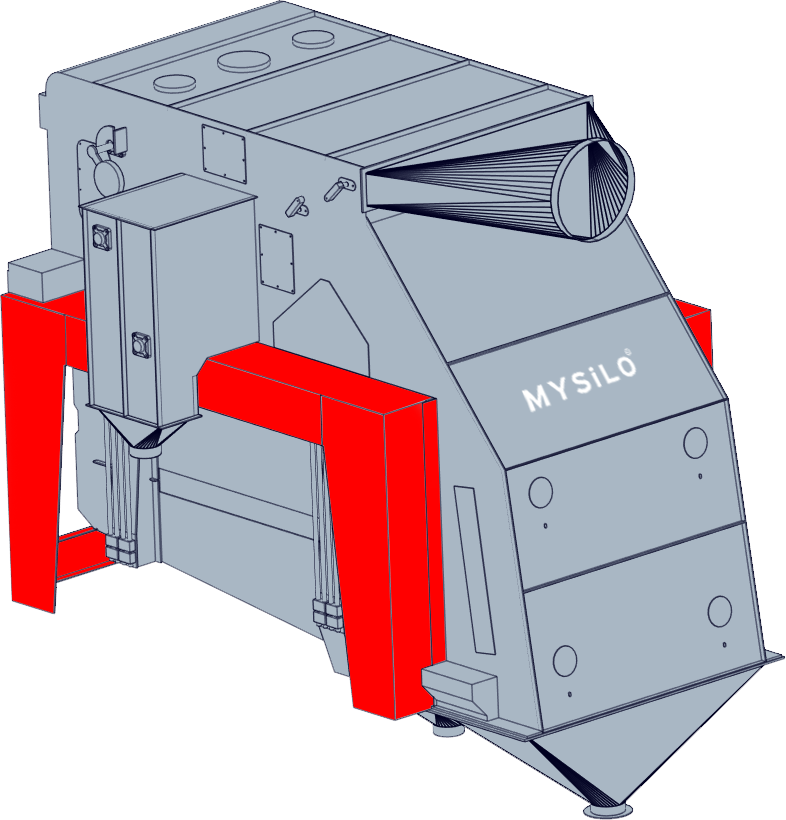

Pre Cleaning - S Model

With its versatile and compact design, the S model grain cleaning machines offer an ideal solution in pre-cleaning processes

PRODUCT FEATURES:

With its versatile and compact design, the S model grain cleaning machines offer an ideal solution in pre-cleaning processes The grain entering the machine is first passed through the air channel, and the dust is separated. It then passes through oscillating screens on the horizontal axis. In this way, both rough wastes and small wastes are separated from the grain according to the sieve holes. It consists of a double sieve set. Top screens remove unwanted particles by separating rough waste.

In addition, it provides system safety. The lower screens separate small particles from the product. Depending on the capacity, more precise cleaning can be done.

-The product is evenly distributed on the sieve surface and maximizes the use of the surface.

- It creates maximum sieving area by keeping the distances between the sieve holes at the lowest level.

- Provides high performance with minimum energy use.

- Provides easy sieve cleaning thanks to the self-cleaning sphere system.

STANDARD EQUIPMENTS:

- Air Channel

- Sieve Set (1 Piece)

- Motor - Product Discharge Adaptor

- Automated Cleaning Spheres

OPTIONAL EQUIPMENTS:

- Cyclone Jet-Pulse Filter

- Aspiration

- Piping System

- Compressor

- Air Lock

| Model | C-S121522 | C-S241544 | C-S241562 | C-S322044 | C-S322062 | C-S482066 |

|---|---|---|---|---|---|---|

| Capacity (t/h) | 60 | 120 | 130 | 160 | 150 | 250 |

| Sieve Area (m²) | 12 | 24 | 24 | 32 | 32 | 48 |

| Upper Sieve Area (m²) | 6 | 12 | 6 | 16 | 8 | 24 |

| Lower Screen Area (m²) | 6 | 12 | 18 | 16 | 24 | 24 |

| Air Need (m³/dk) | 140 | 195 | 195 | 260 | 260 | 390 |

| Main Engine / kW | 3 | 3 | 3 | 4 | 4 | 4 |

| Weight / KG | 4750 | 6250 | 6050 | 7250 | 7050 | 8750 |