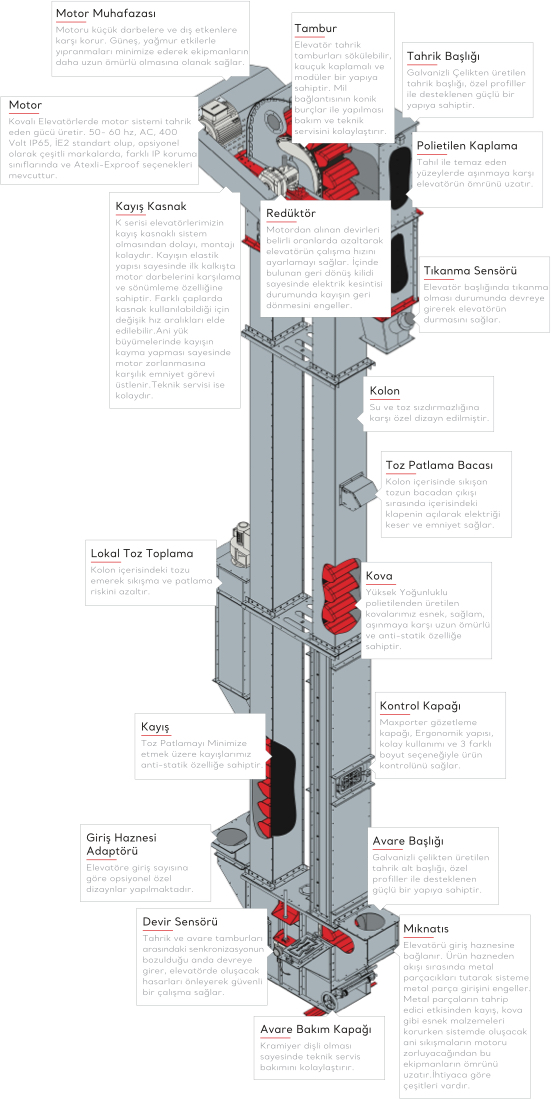

Thanks to the buckets attached to the belt in the bucket elevator, it allows the grains to be transported vertically. Our elevators work quietly at high capacity with lower energy consumption.

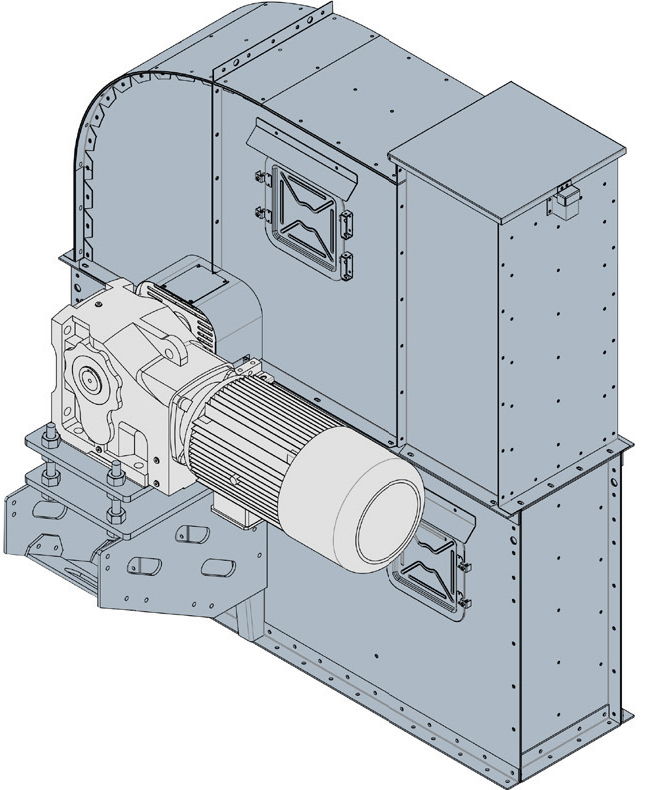

Our H Model elevators are driven by shaft mounted helical reducer with belt pulley connection.

Since pulleys of different diameters can be used, different speeds and capacities are obtained.

Technical Service is easy.

The drive head is driven both as a belt pulley (KK Series) and coupled (AR Series).

Thanks to the return lock, the back-up of the system is prevented in case of power failure, thus providing ease of maintenance.

Our buckets, produced from high-density polyethylene, are flexible, durable, long-lasting against abrasion and have anti-static properties.

Close

The drive sub-head made of galvanized steel has a strong structure supported by special profiles.

CloseThe bucket elevator has different models and product options from 25 t/h to 1000 t/h.

Our bucket elevators are manufactured from galvanized sheet, so they are highly resistant to environmental factors.

Thanks to the anti-static feature of our high-density polyethylene buckets and belts, they are designed to last longer than their counterparts.

It has a modular and standard structure.

In general, our Maxporter bucket elevators are environmentally friendly and designed in accordance with occupational health and safety rules.

According to the motor connections, coupled (A series) belt connection (C series) 2 connections are offered.

Due to the modular and standard structure of our designs, spare parts supply and technical service are easy.

| CODE | DIA | CAPACITY | A | B | C | D | E | G | H | I | J | K |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 31G-25 | 314 | 33 | 1090 | 1540 | 900 | *** | 296 | 168 | 168 | 168 | 168 | 1250 |

| 53H-50 | 530 | 65 | 1600 | 1950 | 1030 | 292 | 350 | 219 | 219 | 219 | 219 | 1930 |

| 63J-100 | 630 | 130 | 1750 | 2400 | 1025 | 267 | 400 | 273 | 273 | 273 | 273 | 1167 |

| 79K-150 | 790 | 195 | 2250 | 2900 | 1450 | 367 | 450 | 323 | 323 | 323 | 323 | 1367 |

| 97K-200 | 970 | 260 | 2500 | 3300 | 1450 | 367 | 450 | 323 | 323 | 323 | 323 | 1367 |

| 107M-300 | 1070 | 390 | 2750 | 3600 | 1700 | 330 | 550 | 406 | 406 | 406 | 406 | 1530 |

| 122L-400 | 1220 | 520 | 2800 | 3700 | 1700 | 330 | 990 | 457 | 457 | 457 | 457 | 1730 |

| 122L-400 | 1220 | 520 | 2800 | 3700 | 1700 | 330 | 990 | 457 | 457 | 457 | 457 | 1730 |

| 107M2-500 | 1070 | 650 | 2850 | 3700 | 1700 | 330 | 670 | 457 | 457 | 457 | 457 | 1730 |

| 122M2-600 | 1220 | 780 | 2850 | 3700 | 1700 | 330 | 990 | 508 | 508 | 508 | 508 | 1730 |

| 122M2-700 | 1220 | 910 | 2850 | 3700 | 1700 | 330 | 990 | 508 | 508 | 508 | 508 | 1730 |

| 122M2-800 | 1220 | 1040 | 2850 | 3700 | 1700 | 330 | 1190 | 609 | 609 | 609 | 609 | 1730 |

| 122M2-900 | 1220 | 1170 | 2850 | 3700 | 1700 | 330 | 1190 | 609 | 609 | 609 | 609 | 1730 |

| 122M3-1000 | 1220 | 1300 | 2850 | 3700 | 1700 | 330 | 1500 | 609 | 609 | 609 | 609 | 1730 |

| 122L3-1000 | 1220 | 1560 | 2850 | 3700 | 1700 | 330 | 1810 | 609 | 609 | 609 | 609 | 1730 |

| Our Unit of Capacity is m³/h. | ||||||||||||

| Diameters found in the table are specified as drum diameter. | ||||||||||||

| Dimensions are in mm. | ||||||||||||

| Maxporter reserves the right to change specifications. | ||||||||||||

| Distance x between Inlet and Discharge chamber is variable depending on the project. | ||||||||||||

Thanks to the buckets attached to the belt in the Bucket Elevator, it allows the grains to be transported in the vertical direction. Our elevators work quietly at high capacity with lower energy consumption.