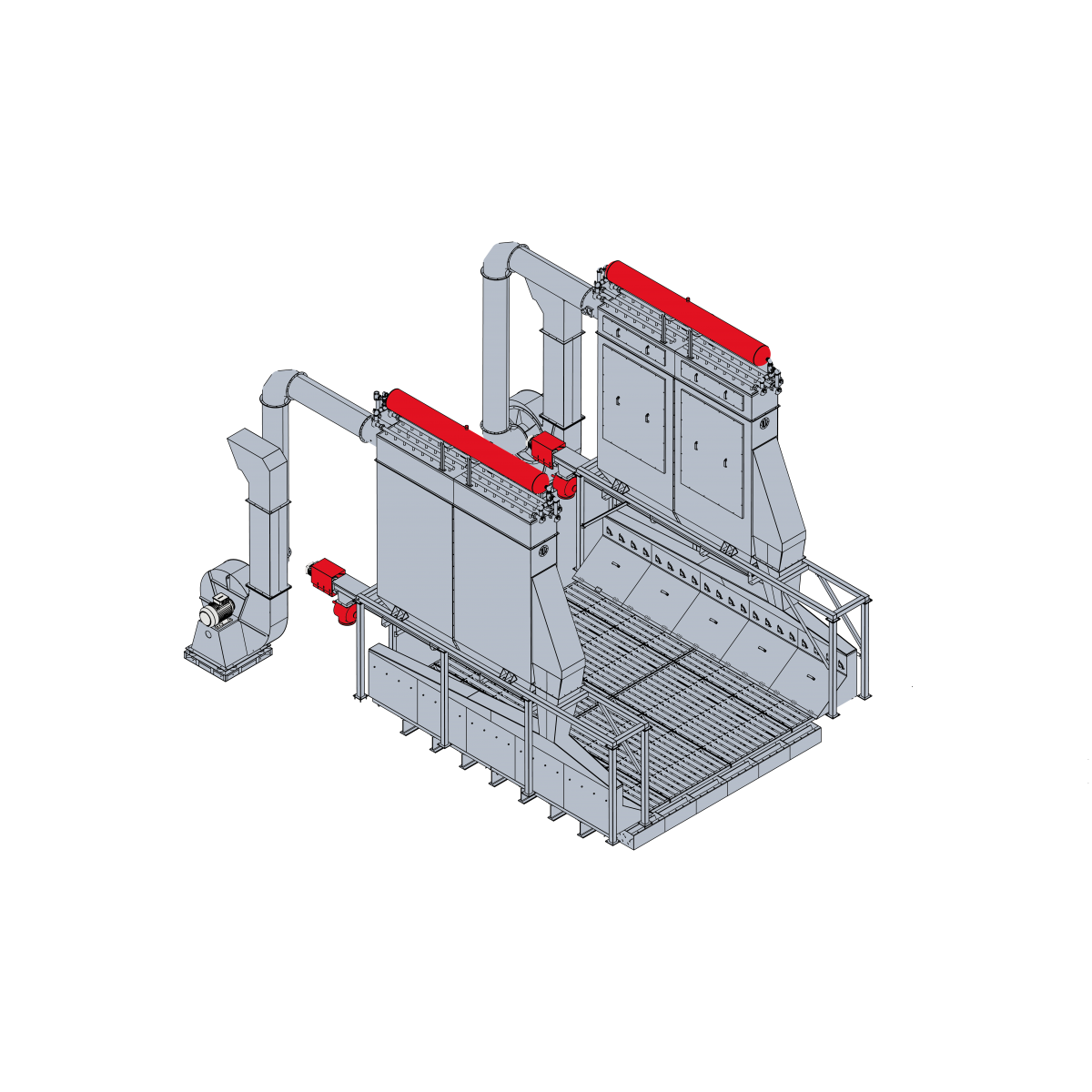

Dust Collection - BF Model

Covered Dust Collection System; It is used to collect the dust that spreads to the environment during product discharge. It is designed to achieve the highest efficiency according to the type of powder.

Working Principle:

Grain products poured into the product receiving pit pass through the treme grate and special dust-proof covers in order and reach the inside of the treme. The dust formed during this time tends to move upwards. In the specially designed under-treme system, only the covers where the product flow is opened and the dust cannot go up because there is product flow from this section. As soon as the product flow is interrupted, the lid will be closed with the effect of gravity.

Thanks to the aspiration fans, the dust is drawn to the filter panels and collected.

Dust is collected in the filters at the top. By using the Jet – Pulse technique, the accumulated dust is instantly discharged. Thanks to the screw under the panel, the collected dust is removed from the system.

Collected dust; It is optionally re-treated or bagged from the exit of the airlock.

Advantages:

• Easy Installation

• Long Lasting Design

• High dust holding capacity

• Increased product quality and longer storage